ALL >> Business >> View Article

When To Use Spot Drills, Stub Drills, And Jobber Drills For Milling

Milling machines are designed to use special cutting tools to quickly and accurately remove material from a workpiece. There are a wide range of tools that can be used to mill various materials, but some tasks are a little bit more complicated than side milling operations. Drilling is one deceptively simple task that often requires special considerations from machine operators. Drilling an accurate hole normally takes some combination of spot drills, stub length drills, and jobber length drills.

Drilling is so complicated because drill bits are not the most accurate tools. Because drill bits are long and they rotate at high speeds, they tend to oscillate much more than other cutting tools. This means that drill bits can easily “walk” off their mark when they contact a surface that is hard enough to deflect the bit. Using the proper tools can help users avoid this issue and get clean holes every time they need to drill into a workpiece.

...

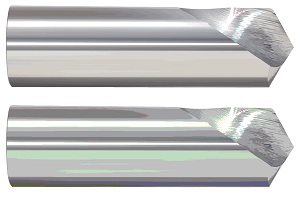

... Spot Drills

The first step when it comes to accurate drilling is the process of spotting. Spotting creates a small dimple on the surface of a workpiece to mark the location of a drill site. Unlike most drill bits, spot drills have very short flute length that rarely extends beyond the tip of the tool. This means that they typically only drill a “hole” that is the size of the tool’s point.

The dimples created by these tools will help larger twist drill bits seat themselves accurately and decrease the likelihood of your twist bit walking off its mark. One important fact to consider when spotting is the point angle. The angle of the spot drill’s tip should be larger than the angle of the twist bit’s drill point in order to ensure that the twist bit contacts the bottom of the spot dimple before the side.

Stub Drills

When the hole that is being drilled does not have to be too deep, using a stub drill is the perfect option. Stub drills, as their name suggests, are shorter in length than your average drill bit. This decreased length helps to increase the tool’s stability at high speeds. For certain materials, stub drills can sometimes be used without spotting and achieve great results. If you have the time, it is always advisable to stop before any drilling operations.

Jobber Drills

The “standard” drill bit is known as a jobber length bit. When you imagine a drill bit, this size is usually the first thing that comes to mind. Jobber bits are characterized by their long twisted flutes along the length of the tool. These bits are crucial for drilling deep holes in your workpiece. Because of their length they are more likely to deflect off a workpiece or miss their mark. This means that it is essential to use a spot drill to mark the location of a hole before employing a larger jobber drill to reach your desired length.

If you need drill bits for your shop, there are a lot of options to choose from. Some of the best high speed cutting tools are constructed from carbide, a metal and ceramic composite material. Tools made from carbide are more rigid and heat resistant than high speed steel alloys. One great American manufacturer of solid carbide drill bits and milling cutters is Online Carbide. You can see their complete inventory of products, including spot drills, stub drills, and jobber drills, when you visit their online store at www.onlinecarbide.com.

For more information about Buy Carbide Drills and Drill Mills Please visit : Online Carbide.

Add Comment

Business Articles

1. Lucintel Forecasts The Global Floral Perfume Market To Grow With A Cagr Of 6.8% From 2024 To 2031Author: Lucintel LLC

2. Lucintel Forecasts The Global Flip Flop Market To Grow With A Cagr Of 3.9% From 2024 To 2031

Author: Lucintel LLC

3. Best Manual Toothbrush In Uae: A Complete Guide To Smarter Oral Care Choices

Author: Smile Cart

4. Boost Your Tour Travel And Adventure Company With Expert Web Design And Seo Digital Marketing Services In Spain

Author: Vikram kumar

5. Lucintel Forecasts The Global Eye Shadow Market To Grow With A Cagr Of 6.2% From 2024 To 2031

Author: Lucintel LLC

6. Lucintel Forecasts The Global Comic Book Market To Grow With A Cagr Of 6.6% From 2024 To 2031

Author: Lucintel LLC

7. How Optical Prototyping Services In Spain Support Product Development

Author: Fotonica Gileyva

8. How Complex Optical Design In Madrid Supports High-tech Industries

Author: Fotonica Gileyva

9. Lucintel Forecasts The Global Coffee Beauty Product Market To Grow With A Cagr Of 5.9% From 2024 To 2031

Author: Lucintel LLC

10. Plaster Sand (plastering Manufactured Sand) Vs River Sand

Author: DOCTORSAND

11. How To Select The Right Chemical Injection System Suppliers For Oil & Gas Operations

Author: Priyadharshini

12. Lucintel Forecasts The Global Cc Cream Market To Grow With A Cagr Of 7.1% From 2024 To 2031

Author: Lucintel LLC

13. Maximizing Brand Growth: Why Dubai Businesses Are Partnering With Specialized Social Media Agencies

Author: Al murooj solutions

14. Create Your Website Easily With Host Sonu: A Step-by-step Tutorial

Author: contentcaddy

15. Unlock Power: Host Sonu Vps 8 Vcpu 16 Gb Ram Plan Explained

Author: contentcaddy